Multilayer PCB manufacturing involves complex processes to create high-density interconnections. Advanced techniques like lamination, etching, and plating are utilized to produce durable, reliable circuit boards that power modern electronics.

Check all the data provided to make sure the designing of the PCB is manufacturable, functional, reliable and cost effective. Raise questions if EQ, then issue MI for production.

Cut the materials into panel according to MI. Including core, Prepreg, copper foils. Tooling holes need to be drilled at this step.

Prepare for the inner layer DFR(Dry Film Resist) lamination. To increase DFR adhesion, etch the surface of copper foils by jet-scrubber, buffbrushing.

Laminate Dry Film on cores. D/F is used as a photosensitive material forphotolithography.

Expose light onto the D/F.LDI (Laser Direct Imaging),which doesn't require mask application,is analternative solution.

Same as the following. Developing the photoresist; Etching away unwanted copper; Stripping the remaining resist to reveal the circuit pattern.

Etch the surface of copper surface to ensure adhesion of coppe and Prepreg.

Laminate Dry Film on cores. D/F is used as a photosensitive material forphotolithography.

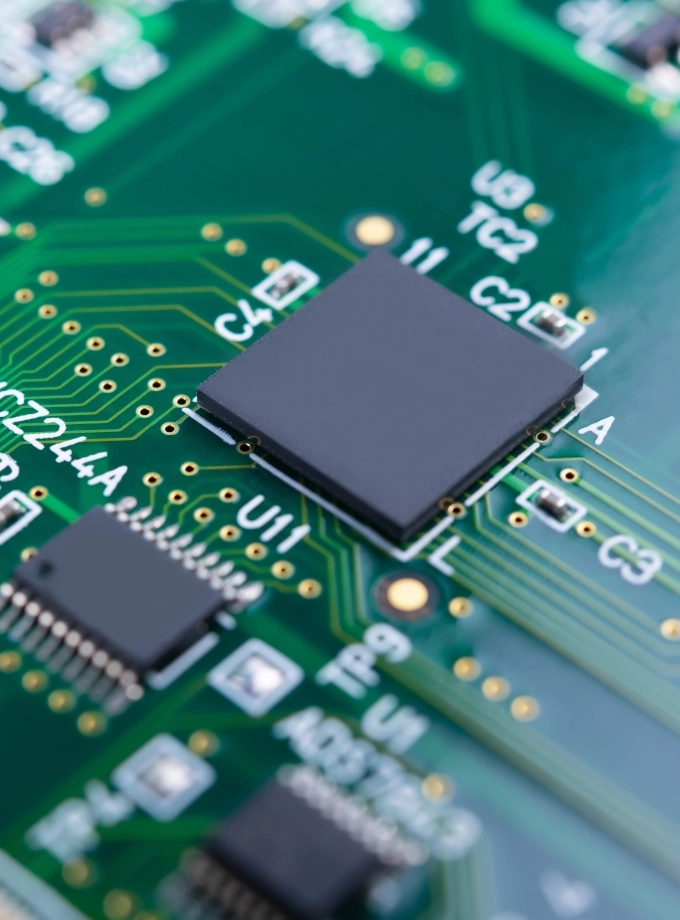

Heat the laminated layers under pressure in a vacuum melt Prepreg by heat to multilayer PCB formation. Other processes by the following will be the same as a double-sided PCB.

Drill on board to form through holes.

Remove the smear and resin residues left in the drilled holes, to ensure good electrical connectivity and improve the copper plating quality.

Electroless Copper Plating, a thin layer of copper is deposited on the hole walls through a chemical process, making them conductive.

Electroplating, the thin copper layer is further reinforced with additional copper through electroplating, ensuring robust andreliable electrical connections.

Prepare for the next step, D/F lamination. To increase dry film adhesion, etch the surface of copper foils by jet-scrubber,buff brushing.

Laminate Dry Film on copper foils. D/F is used as a photosensitive material for photolithography.

Apply masks(films) on D/F and expose light onto the surface of copper foils. Currently, we use both ways, D/Fand LDI(Laser Direct Imaging), which doesn't require mask application.

Developing the photoresist; Etching away unwanted copper; Stripping the remaining resist to reveal the circuit pattern.

Use AOI for outer layer inspection, to check for defects such as scratches, misalignments, and incomplete etching, ensuring the final board meets the required specification.

Clean and roughen the copper surface to increase the adhesion between the copper surface and solder resist.

Apply photosolder resist on one side then pre-baking, then printing solder resist on the other side, pre-baking, then exposure-develop-curing.

Screen printing or injet printer printing the legend.

Apply surface treatment according to the specification, like Lead-free HASL, OSP, Immersion Gold/Tin/Ag etc.

CNC routing, V-scoring, or punching, to de-panel the board from working panel.

Use Probe flying testing for prototype and small series, and E-test fixture for production orders.

Final Quality Control and Final Quality Assurance for the finished PCB.

Packing according to the specification and ship to worldwide customers.

Basic PCB with copper layer on one side

Circuits on both sides, interconnected

Stacked-layer PCB for complex electronics

High density PCB with laser drilling microvias

PCB with thick copper layers for high current

PCB optimized for high-frequency signal integrity

Robust PCB for modular system connectivity

PCB with metal core for improved heat dissipation

Thin, bendable PCB for flexible electronics

PCB combining both rigid and flexible layers

FR-4 PCB with depth controlled milling technology

PCB for high-efficiency MiniLED displays

Eco-friendly PCB with halogen-free materials

Durable PCB made by Polyimide material

High-performance, miniaturized base for IC

Embedded parts in PCB for space-saving integration

Passive component that limits electrical current flow

Stores and releases electrical energy in circuits

storing energy through magnetic fields

Amplify or switch electronic signals

Convert voltages and isolate circuits electrically

Energy-efficient, long-lasting light source

Compact components for complex electronic functions

Controls the flow of electricity

Join electrical circuits for signal transmission

Protects circuits from overloads and damage

Materials that control electrical current flow

Stores and provides electrical energy

Transmission and reception of radio frequency signals

Devices with electrical and mechanical components

Protect and control electrical power circuits

Conduct and connect electrical power and signals

Laser-cut stencil for accurate components placement

Surface Mount assembly with Reflow soldering

Through-hole parts using DIP and wave soldering

Both SMT and DIP components on one board

PCB assembly without the use of lead solder

Programming integrated circuits for specific functions

Repair of Ball Grid Array (BGA) chips

Protective coating to against moisture and contaminants

Process of shaping materials by injecting into molds

Testing to verify product's function and performance

Soldering pre-made cables and wires on board

Test to simulate long-term wear and performance

Electronic component integration into enclosures

Electronic Manufacturing Services

Customer sources some parts and we handle the rest

Complete assembly service from design to final product

Discovering identities and building connections

Building stability, balance, and power

Commitment to excellence and continuous improvement

Reach out, connect, and explore solutions

The PCB assembly process is a systematic sequence that transforms a bare PCB into a functional electronic device. It involves multiple stages utilizing specialized equipment and quality controls, ensuring reliable and efficient integration of components according to design specifications.

Initial inspection and verification of received materials, including bare PCBs and components, before they enter the assembly process, to ensure that materials comply with customer requirements and specifications.

Baking the bare PCBs and the moisture-sensitive components(such as certain ICs, BGAs, and plastic-packaged components) prior to assembly.

Prepare for the inner layer DFR(Dry Film Resist) lamination. To increase DFR adhesion, etch the surface of copper foils by jet-scrubber, buffbrushing.

Laminate Dry Film on cores. D/F is used as a photosensitive material forphotolithography.

Expose light onto the D/F.LDI (Laser Direct Imaging),which doesn't require mask application,is analternative solution.

Same as the following. Developing the photoresist; Etching away unwanted copper; Stripping the remaining resist to reveal the circuit pattern.

Etch the surface of copper surface to ensure adhesion of coppe and Prepreg.

Laminate Dry Film on cores. D/F is used as a photosensitive material forphotolithography.

Heat the laminated layers under pressure in a vacuum melt Prepreg by heat to multilayer PCB formation. Other processes by the following will be the same as a double-sided PCB.

Drill on board to form through holes.

Remove the smear and resin residues left in the drilled holes, to ensure good electrical connectivity and improve the copper plating quality.

Electroless Copper Plating, a thin layer of copper is deposited on the hole walls through a chemical process, making them conductive.

Electroplating, the thin copper layer is further reinforced with additional copper through electroplating, ensuring robust andreliable electrical connections.

Prepare for the next step, D/F lamination. To increase dry film adhesion, etch the surface of copper foils by jet-scrubber,buff brushing.

Laminate Dry Film on copper foils. D/F is used as a photosensitive material for photolithography.

Apply masks(films) on D/F and expose light onto the surface of copper foils. Currently, we use both ways, D/Fand LDI(Laser Direct Imaging), which doesn't require mask application.

Developing the photoresist; Etching away unwanted copper; Stripping the remaining resist to reveal the circuit pattern.

Use AOI for outer layer inspection, to check for defects such as scratches, misalignments, and incomplete etching, ensuring the final board meets the required specification.

Focus on quick turnaround prototype, small to medium PCB manufacturing since 2010.