HDI PCB Key Features High-Density Interconnect (HDI) PCBs are advanced circuit boards designed for complex, high-density electronic assemblies. The key

Home > Blog > PCB Manufacturing > HDI2

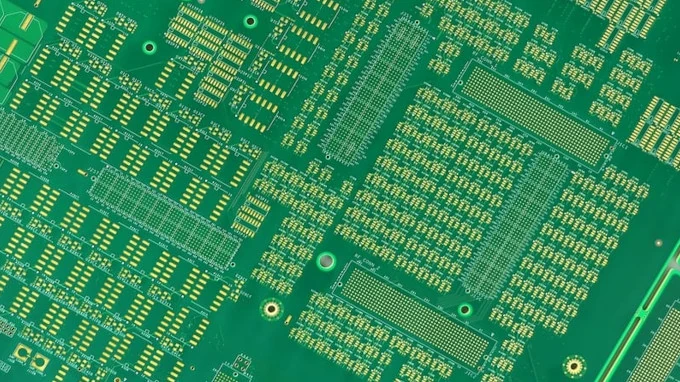

High-Density Interconnect (HDI) PCBs are advanced circuit boards designed for complex, high-density electronic assemblies. The key features of HDI PCBs include:

HDI PCBs utilize microvias—small-diameter vias typically drilled with laser technology—to create interlayer connections. These microvias are often only a few mils in diameter and allow for high interconnection density while preserving space for routing.

HDI technology incorporates blind vias (connecting outer layers to internal layers without passing through the entire PCB) and buried vias (restricted to internal layers), which enable more routing channels and reduce via count on outer layers, enhancing signal integrity and miniaturization.

HDI PCBs use very thin dielectric layers and reduced circuit layer spacing, facilitating finer line widths and spacings, which contribute to increased circuit density and higher performance at high frequencies.

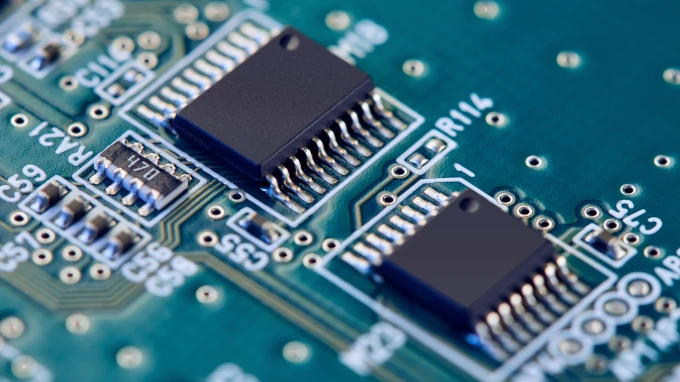

The stacking of multiple layers with microvias allows for complex, multi-layer interconnections in a compact form factor, supporting advanced applications like smartphones, tablets, and high-speed computing devices.

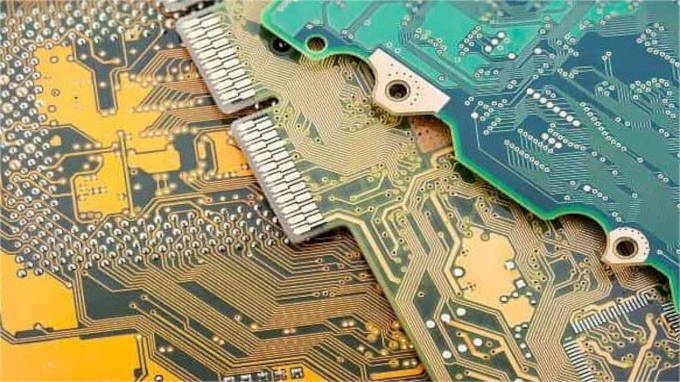

To achieve high performance, HDI PCBs often employ advanced dielectric substrates and high-quality prepregs tailored for controlled impedance and high-speed signal transmission.

Combining microvias with via-in-pad and other innovative techniques allows for flexible and intricate board designs, supporting component miniaturization and improved electrical performance.

HDI fabrication relies heavily on laser drilling for microvias, laser Direct Image (LDI) processes, and precise lamination to ensure accurate via formation and reliable interlayer connections.

Reduced via sizes and optimized layer stacks improve signal integrity, reduce parasitic inductance and capacitance, and enable high-frequency operation suitable for RF and high-speed digital circuits.

Microvias and advanced materials contribute to better thermal management, mechanical stability, and overall robustness in miniaturized designs.

HDI materials and processes are governed by standards such as IPC-4104, which define classifications, quality requirements, and manufacturing best practices to ensure consistency and reliability.

HDI PCB Key Features High-Density Interconnect (HDI) PCBs are advanced circuit boards designed for complex, high-density electronic assemblies. The key

Lead-free HASL (Hot Air Solder Leveling) and ENIG (Electroless Nickel Immersion Gold) are two common PCB surface finishes. Lead-free HASL

Reflow soldering temperature setting is a precise and critical process in electronics manufacturing, as it determines the quality and reliability

Lead-free HASL (Hot Air Solder Leveling) and ENIG (Electroless Nickel Immersion Gold) are two common PCB surface finishes. Lead-free HASL offers good solderability and is cost-effective but can

Lead-free HASL (Hot Air Solder Leveling) and ENIG (Electroless Nickel Immersion Gold) are two common PCB surface finishes. Lead-free HASL offers good solderability and is cost-effective but can

Lead-free HASL (Hot Air Solder Leveling) and ENIG (Electroless Nickel Immersion Gold) are two common PCB surface finishes. Lead-free HASL offers good solderability and is cost-effective but can

Laminated Structure of Multilayer PCBs Lead-free HASL (Hot Air Solder Leveling) and ENIG (Electroless Nickel Immersion Gold) are two common PCB surface finishes. Lead-free HASL offers good solderability