Home > Metal Core PCB

Metal Core PCBs (MCPCBs) are advanced circuit boards designed with a metal base layer, typically aluminum or copper, to provide superior heat dissipation and mechanical stability. Unlike traditional FR4 boards, MCPCBs incorporate a thermally conductive dielectric layer that efficiently transfers heat from components to the metal substrate, preventing overheating and enhancing reliability. Aluminum-based PCBs are lightweight, cost-effective, and widely used in LED lighting, power supplies, and consumer electronics. Copper-based PCBs offer higher thermal conductivity and strength, making them suitable for high-power applications such as automotive, aerospace, and defense systems. With excellent thermal management, durability, and performance, MCPCBs are the ideal solution for modern high-density, high-power electronic designs.

Typical substrates used for Single-Sided Circuit Boards are XPC, FR-1, FR-2, FR-4, CEM-1, CEM-3.

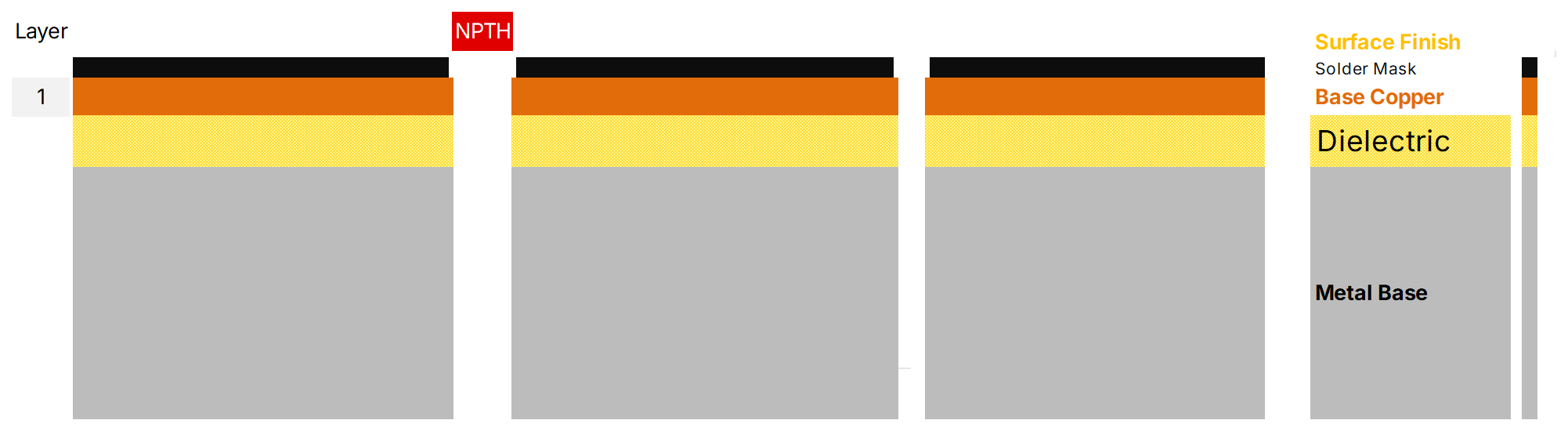

Using standard ED printed circuit copper foils with thicknesses ranging from 0.5oz to 10oz (17-350um).

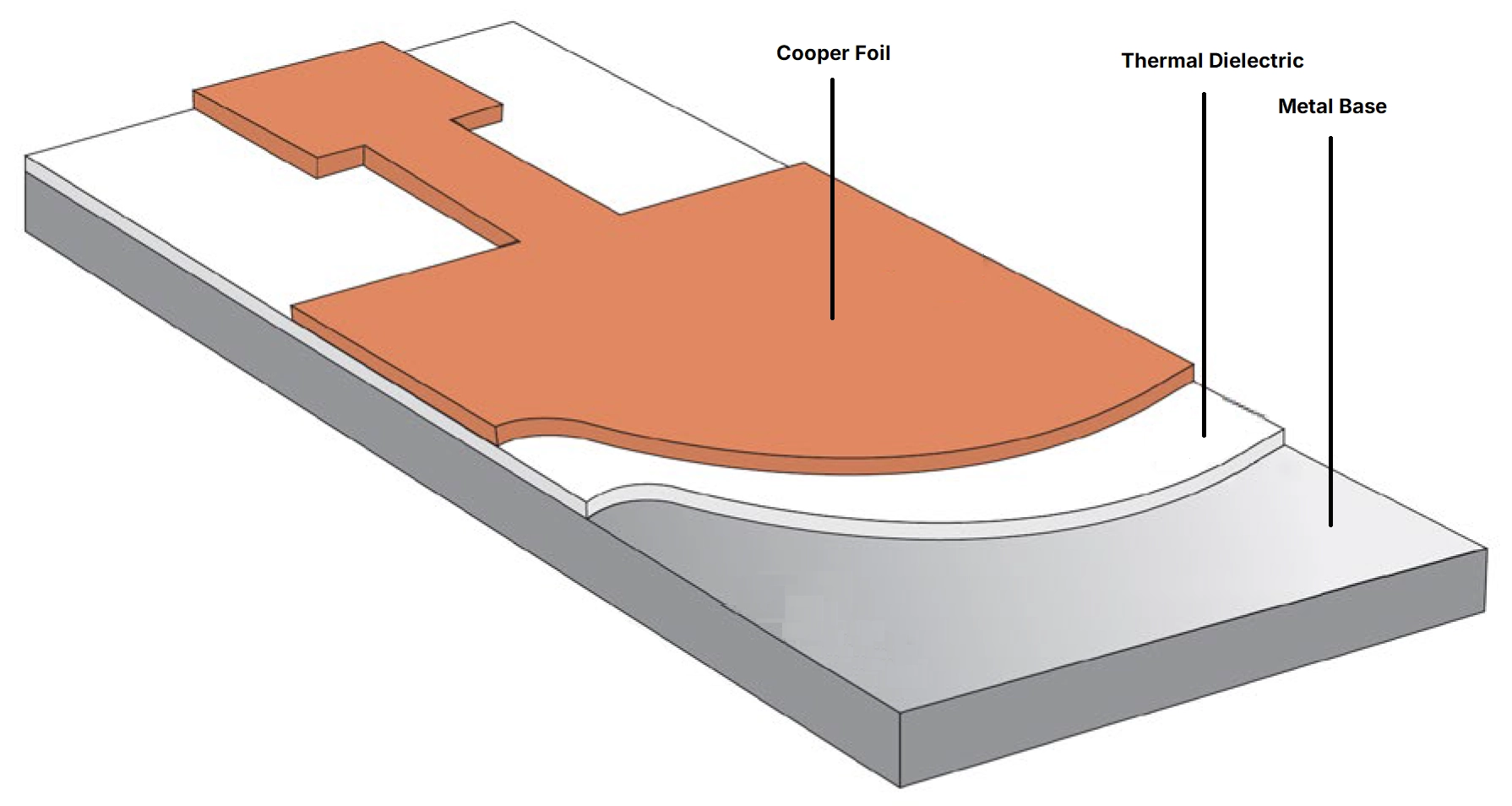

The dielectric layer is thermally conductive with excellent electrical strength and is the bonding layer from the circuit to metal base.

Often aluminum, but other metals such as copper can be used. The base materials are available in a variety of standard gauge thicknesses, typically 1.5mm.

Aluminum-Based PCBs are a type of single-sided printed circuit board that use aluminum as the base material instead of traditional substrates like FR-1 or FR-4. The aluminum base provides excellent heat dissipation and strength, making this type of PCB ideal for applications that require high thermal management, such as LED lighting systems and power converters. These boards are known for their durability and ability to support high-power components while maintaining performance reliability.

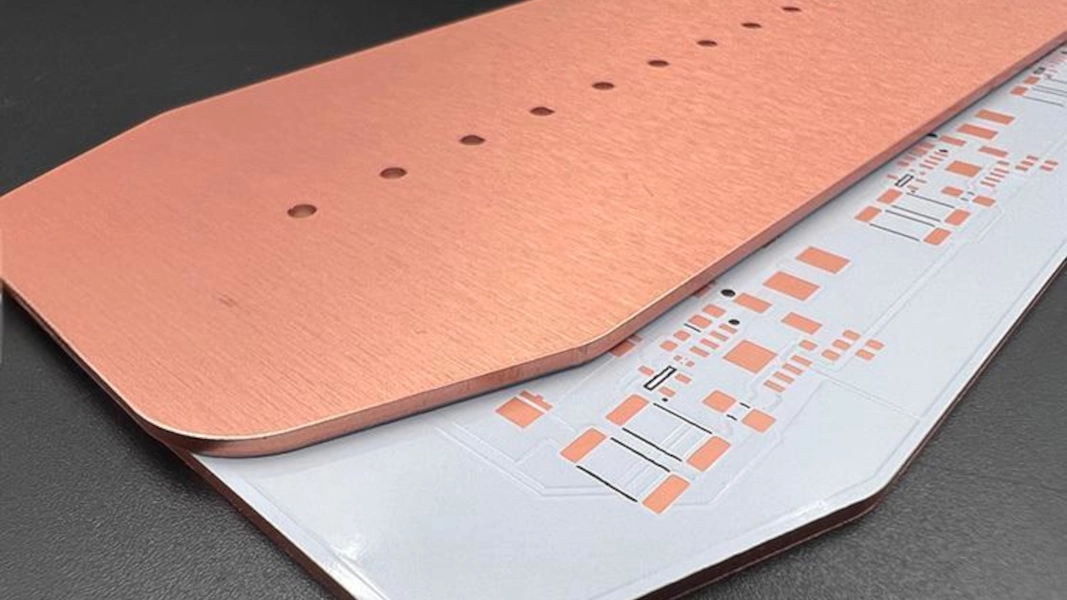

Copper-Based PCBs are a type of printed circuit board that use copper as the base material instead of traditional substrates. These PCBs are known for their excellent electrical conductivity and are typically used in applications requiring high-performance electrical connections. The copper base enhances thermal conductivity, making them suitable for power electronics, motor controllers, and other applications where efficient heat dissipation and signal integrity are critical. Being durable and reliable, copper-based PCBs are widely adopted in industries requiring precision and performance.

| Metal Core PCB Feature | Technical Specification |

|---|---|

| Layer Count | 1~4L |

| Type of MCPCB | Aluminum, Copper, Iron Based, Thermalelectric Separation |

| Aluminum Type | 3003, 5052, 6061 |

| Dielectric Thickness | 50um, 60um, 75um, 100um, 120um, 150um, 180um etc. |

| Laminate Vendor | Bergquist, Ventec, Polytronics, BoYu, ShengYi, TOTKING etc. |

| Thermal Conductivity | 0.5~12 W/ m.K(normal), 175~380W/m.K(Thermal Electric Separation) |

| Finished Board Thickness | 0.4~4.0 mm |

| Copper Thickness | 0.5~6 OZ |

| Solder Mask Vendor | Taiyo, Lanbang, Coants, KSM etc. |

| Solder Mask Color | White, Black, Red, Blue, Yellow etc. |

| Surface Finishing | Immersion Gold/ Tin/ Silver, OSP, Lead free HAsL etc. |

| Profile Type | Routing, Punching, Laser Cutting, V-Scoring |

| Bow and Twist | ≤ 0.75% |

| Min. Hole Size | 0.5 mm |

| Max. Board Size | 580 x 1500 mm |

| Min. Trace Width & Spacing | 4/4 mil |

| Max. Electric Resistance | AC 8000V |

| Min. Outline Tolerance | ± 0.05 mm |

Essential information includes part numbers, fabrication and drill drawings, manufacturing notes, board details, material specifications, conductor patterns, artwork data for both sides, aperture lists, drill data, netlist data, and any special requirements.

Designers focus on layer count optimization, power/ground plane placement, controlled impedance routing, signal isolation, thermal dissipation, and via structures (blind, buried, or through-hole) for reliable connectivity.

Typical layer counts are 4 to 8 layers, common for consumer electronics and networking and telecom devices.

Typical materials include prepreg (pre-impregnated dielectric sheets), core substrates made from fiberglass-reinforced laminates like FR-4 or specialized materials for high-speed/high-frequency applications, and copper foils. Advanced multilayer PCBs may also use high-speed dielectric substrates like Rogers or PTFE-based materials for specific electrical properties.

Proper layer stacking, controlled impedance routing, and short signal path design help minimize signal reflections, crosstalk, and electromagnetic interference. Careful via placement and ground plane design are critical for maintaining high-speed signal quality and reducing noise.

Higher component density (saves space), improved signal integrity (reduced EMI and crosstalk), better power distribution (dedicated power and ground planes), enhanced durability (rigid structure).

Number of layers (more layers = higher cost), material selection (high-frequency or exotic materials cost more), Via types (blind/buried vias increase cost), tolerances & testing (tight specs require more QA).

Consumer electronics, telecom equipment, aerospace avionics, medical imaging devices, automotive radar systems, and industrial automation heavily rely on multilayer PCB technology.

Electrical testing detects opens/shorts, AOI checks for surface defects, microsection analysis verifies inner-layer integrity, and X-ray inspection ensures proper via filling and solder joint quality.

High layer counts increase board thickness and thermal mass, making reflow soldering more complex. Warpage, fine-pitch BGA soldering, and mixed SMT/through-hole components also require precise assembly techniques.

Common FAQ topics. If you have specific questions in mind, feel free to ask!