Home > PCB Assembly > DIP + Wave

Multilayer PCB consists of multiple conductive copper layers separated by insulating layers, commonly configured with 4, 6, 8 layers and so on. These layers are bonded together using heat and adhesive to form a single, integrated board. The inner layers are made of a substrate material known as the core, and the insulating layers are often referred to as prepreg. Prepreg is a glass-reinforced epoxy material impregnated with resin, and it facilitates the bonding of copper layers. Connections between outer and inner layers are established via plated through holes (PTH) and vias. Multilayer PCB introduces the lamination process, which is where we actually creates the composite PCB from layers of circuitry in a lamination press under high pressure and heat. After pressing, multilayer PCB production is treated almost the same as a traditional double-sided PCB.

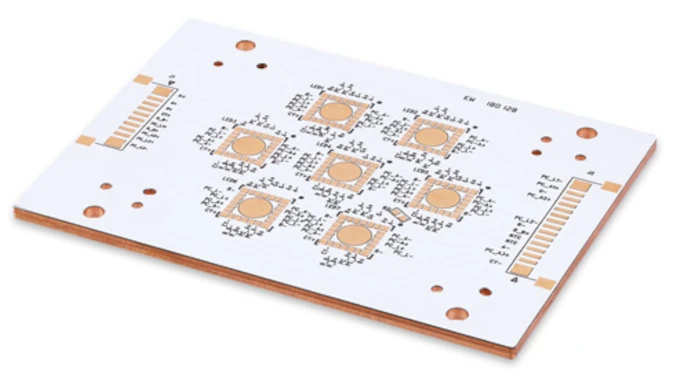

Union Circuits offers a wide range of PCB fabrication services, from single-sided to complex 42-layer boards. Whether you need a few prototypes for testing or large

XPC, FR-1, FR-2 are flame-retardant phenolic materials that are also highly punchable, they have excellent electrical, heat-resistant, moisture-resistant, flame-resistant and other properties as well as low cost. FR-3 is epoxy Copper Clad Laminate, it is flame retardant with high electrical properties.

CEM-1, which is a composite of paper and glass impregnated with epoxy resin, is the most popular substrate for SSBs. While not as low cost as XPC-FR or FR-2, CEM-1 has gained popularity because of its mechanical strength and also because of the relative unavailability of paper phenolic laminates.

CEM-3 is similar to FR4, but uses a composite material of a non-woven glass core and a woven glass surface instead of a full sheet of woven glass. It’s a flame retardant epoxy resin, copper-clad glass material, commonly used in double-sided PCBs.

“FR” is the abbreviation of flame retardant. As the board runs on electricity, it should be heat resistant. FR4 has much better heat resistance than FR1 and XPC due to the different composition of the layers.