Home > PCB Assembly > SMT + Reflow

Laser stencil is a precision tool used in PCB assembly to apply solder paste accurately onto circuit boards. Made from high-quality stainless steel, it features laser-cut apertures that match the board’s design, ensuring consistent and reliable solder paste deposition. Ideal for surface mount technology (SMT), laser stencils enhance efficiency and accuracy in both prototyping and mass production. Their durability and fine detail make them essential for achieving high-quality solder joints and optimal PCB performance.

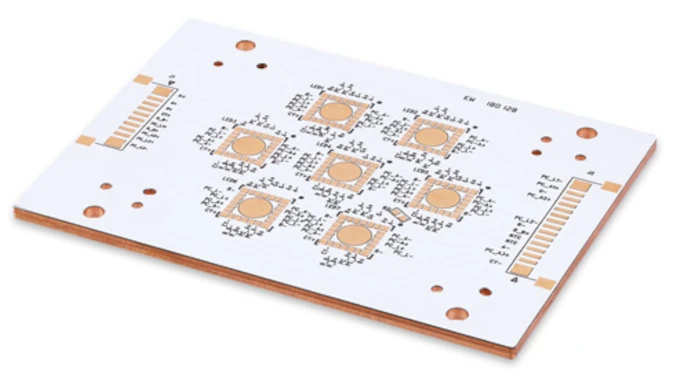

Union Circuits offers a wide range of PCB fabrication services, from single-sided to complex 42-layer boards. Whether you need a few prototypes for testing or large

XPC, FR-1, FR-2 are flame-retardant phenolic materials that are also highly punchable, they have excellent electrical, heat-resistant, moisture-resistant, flame-resistant and other properties as well as low cost. FR-3 is epoxy Copper Clad Laminate, it is flame retardant with high electrical properties.

CEM-1, which is a composite of paper and glass impregnated with epoxy resin, is the most popular substrate for SSBs. While not as low cost as XPC-FR or FR-2, CEM-1 has gained popularity because of its mechanical strength and also because of the relative unavailability of paper phenolic laminates.

CEM-3 is similar to FR4, but uses a composite material of a non-woven glass core and a woven glass surface instead of a full sheet of woven glass. It’s a flame retardant epoxy resin, copper-clad glass material, commonly used in double-sided PCBs.

“FR” is the abbreviation of flame retardant. As the board runs on electricity, it should be heat resistant. FR4 has much better heat resistance than FR1 and XPC due to the different composition of the layers.