Inductors use the magnetic effects of electrons traveling in wires to influence the travel speed of other electrical signals. Typically inductors are a coil configuration. No special material technology has been demonstrated for inductors. These spirals of copper circuitry are typically formed similarly to the copper-conductive traces of innerlayers. Formed inductors are current loops configured to induce a magnetic field for storing and controlling inductive energy. Inductance (measured in henry) is an effect that results from the magnetic field that forms around a current carrying conductor. Current flowing through the inductor creates a magnetic field that has an associated electromotive-field that opposes the applied voltage. This counter electromotive-force (emf) generated opposes the change in voltage applied to the inductor and current in the inductor resists the change but does rise. This is known as inductive reactance. It is opposite in phase to capacitive reactance. Routing the circuit conductor into a spiral creates a larger magnetic field that can increase inductance.

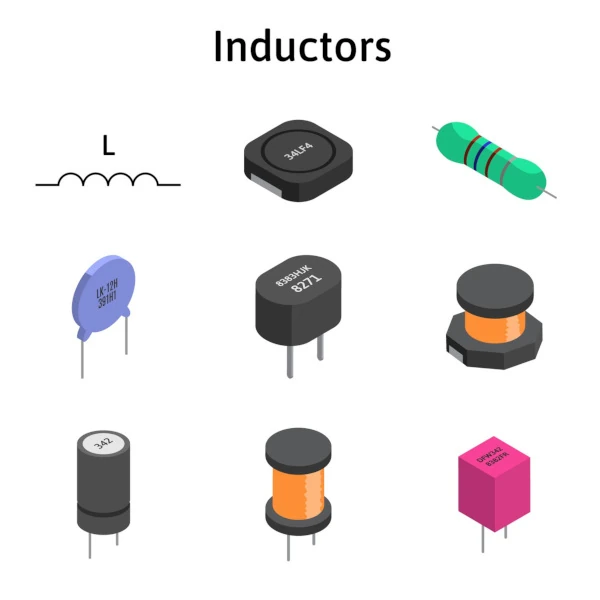

Various types of Inductors, we can source.

Types of Inductors

Air core inductors have the advantages of low DC impedance, large allowable current, high Q value, small size, light weight, low cost, easy manufacturing, and easy integration. They are suitable for circuits that require high frequency and high Q such as mobile communication equipment.

Air core inductors have the advantages of low DC impedance, large allowable current, high Q value, small size, light weight, low cost, easy manufacturing, and easy integration. They are suitable for circuits that require high frequency and high Q such as mobile communication equipment.

Coupled inductors are inductive components, also called self-inductance components. They are two or more coils, and the magnetic flux generated by each of these coils intersects with the other coil.

Coupled inductors are inductive components, also called self-inductance components. They are two or more coils, and the magnetic flux generated by each of these coils intersects with the other coil.

The core of a laminated core inductor is made up of multiple layers of sheets, usually using insulating material as an isolation layer to prevent short circuits between layers. Multilayer core inductors have the characteristics of high inductance value, low DC resistance, good temperature stability and high saturation current capability.

The core of a laminated core inductor is made up of multiple layers of sheets, usually using insulating material as an isolation layer to prevent short circuits between layers. Multilayer core inductors have the characteristics of high inductance value, low DC resistance, good temperature stability and high saturation current capability.

Chokes inductor is very simple, but it is specially designed to block (choke) high-frequency signals. It consists of a coil of insulated wire wound on a magnetic core. The main difference between chokes and other inductors is that they do not require high Q factor construction techniques, which aim to reduce the resistance in inductors found in tuned circuits.

Chokes inductor is very simple, but it is specially designed to block (choke) high-frequency signals. It consists of a coil of insulated wire wound on a magnetic core. The main difference between chokes and other inductors is that they do not require high Q factor construction techniques, which aim to reduce the resistance in inductors found in tuned circuits.

Variable inductors, also known as adjustable inductors, are electrical components that allow the inductance value to be varied or adjusted. Inductance is a measure of the opposition of a circuit element to changes in electric current passing through it, creating a back electromotive force (EMF) that opposes the change in current.

Variable inductors, also known as adjustable inductors, are electrical components that allow the inductance value to be varied or adjusted. Inductance is a measure of the opposition of a circuit element to changes in electric current passing through it, creating a back electromotive force (EMF) that opposes the change in current.

Ferrite inductor is an inductor that uses ferrite material as its magnetic core. It has high initial magnetic permeability, excellent stress resistance and excellent temperature characteristics, and do not cause environmental pollution. In addition, ferrite inductors enable the tight tolerances and high reliability of resin molded inductors.

Ferrite inductor is an inductor that uses ferrite material as its magnetic core. It has high initial magnetic permeability, excellent stress resistance and excellent temperature characteristics, and do not cause environmental pollution. In addition, ferrite inductors enable the tight tolerances and high reliability of resin molded inductors.

Iron core inductor consists of a ferrite core and copper wire windings. Iron core inductors have the advantages of good high-frequency characteristics, high Q value, small size, light weight, and low cost. They are widely used in various electronic equipment, such as communications, computers, home appliances and other fields.

Iron core inductor consists of a ferrite core and copper wire windings. Iron core inductors have the advantages of good high-frequency characteristics, high Q value, small size, light weight, and low cost. They are widely used in various electronic equipment, such as communications, computers, home appliances and other fields.

Toroidal inductor, also called self-inductance component. Its structure is one or more coils wound around a toroidal magnetic core. Toroidal inductors feature highly saturable materials, wide inductance range, high current capability, and low DC resistance1. Toroidal inductors are widely used in circuits, such as transformers, coupling circuits, etc.

Toroidal inductor, also called self-inductance component. Its structure is one or more coils wound around a toroidal magnetic core. Toroidal inductors feature highly saturable materials, wide inductance range, high current capability, and low DC resistance1. Toroidal inductors are widely used in circuits, such as transformers, coupling circuits, etc.

Bobbin inductor is made of insulated wires wound with a certain number of turns on a bobbin. The inductance of a bobbin inductor is related to the shape, size, winding method, number of turns, and type of intermediate magnetically conductive material of the coil winding.

Bobbin inductor is made of insulated wires wound with a certain number of turns on a bobbin. The inductance of a bobbin inductor is related to the shape, size, winding method, number of turns, and type of intermediate magnetically conductive material of the coil winding.

Power inductor is used to provide inductance in a circuit to suppress high-frequency noise, filter, regulate current, etc. Power inductors mainly play the functions of choke, filtering and oscillation in the circuit. According to the current changes, power inductors can be divided into high-frequency choke coils and low-frequency choke coils.

Power inductor is used to provide inductance in a circuit to suppress high-frequency noise, filter, regulate current, etc. Power inductors mainly play the functions of choke, filtering and oscillation in the circuit. According to the current changes, power inductors can be divided into high-frequency choke coils and low-frequency choke coils.

Shielded Surface Mount Inductor is commonly used on surface mount technology (SMT) on circuit boards. The main feature of this inductor is its shielding effect, which can reduce electromagnetic interference (EMI) and electromagnetic radiation (EMR), thereby improving the stability and reliability of the circuit. Shielded surface mount inductors usually consist of one or more coils that are encased in a metal shield to prevent electromagnetic fields from affecting the surrounding circuitry.

Shielded Surface Mount Inductor is commonly used on surface mount technology (SMT) on circuit boards. The main feature of this inductor is its shielding effect, which can reduce electromagnetic interference (EMI) and electromagnetic radiation (EMR), thereby improving the stability and reliability of the circuit. Shielded surface mount inductors usually consist of one or more coils that are encased in a metal shield to prevent electromagnetic fields from affecting the surrounding circuitry.

Molded inductors are made by pressing components such as magnetic cores and coils in a mold. Molded inductors are widely used in electronic equipment due to their small size, light weight, solid structure, and high reliability. They are often used in circuits such as filtering, noise suppression, impedance matching, and signal transmission to improve circuit performance and stability.

Molded inductors are made by pressing components such as magnetic cores and coils in a mold. Molded inductors are widely used in electronic equipment due to their small size, light weight, solid structure, and high reliability. They are often used in circuits such as filtering, noise suppression, impedance matching, and signal transmission to improve circuit performance and stability.

Top Inductor Manufacturers

Popular used Inductor manufacturers, ranking in no particular order.

distributors

Worldwide first-classs distributors, ranking in no particular order.

Our Services

Discover our diverse services customized for your needs. From design to execution, we’ve got it all.

Single Component Sourcing

Efficiently source one single components with our streamlined process. Save time and resources today.

Multiple Components Sourcing

Efficiently source multiple components with our streamlined processes and expert team.

Entile BOM Components Sourcing

Leave the tough sourcing job to us, just enjoy a cup of coffees time you can get a prompt response.

NRND Components Sourcing

Sourcing for alternative components, managing obsolescence risks, and ensuring the availability and reliability of critical components.

Hard-to-find Components Sourcing

Acquiring rare, discontinued, or difficult-to-obtain components by our our extensive network and experience.

Stock Management

Balancing inventory levels to ensure the availability parts when needed, minimizes stockouts and overstocking and helps maximize profitability.