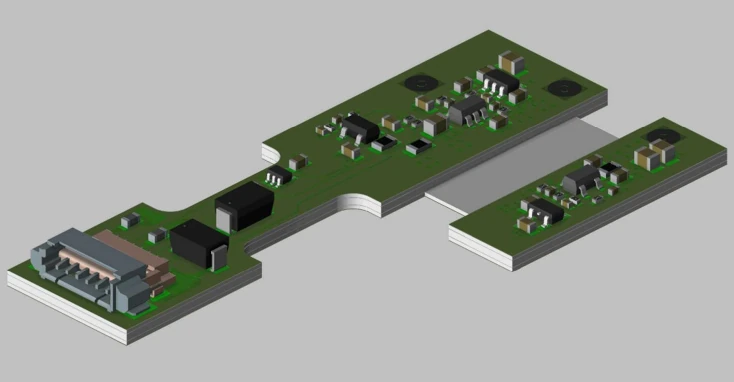

Like rigid-flex PCBs, semi-flex PCB combines the benefits of both rigid and flexible boards, it offers a solution in electronic circuit design providing stability like rigid PCBs and versatility like flexible PCBs in specific areas.

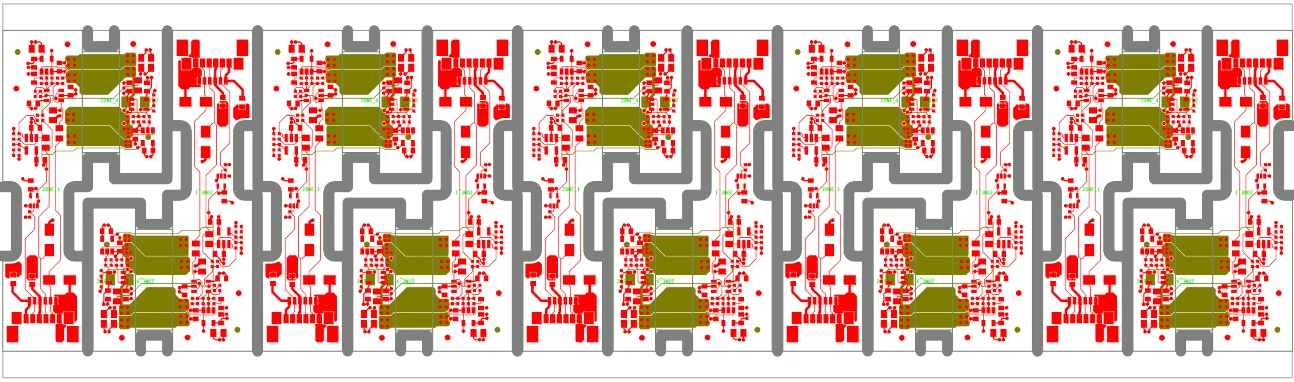

Semi-flex PCB is usually made of standard FR-4 or some other rigid material with depth controlled milling to form the specific thinnest bending area, the bending area will be covered by flexible solder mask or coverlay used for flexible circuits. As the bending area is FR-4 and very thin, it is only suitable for applications need only a few bending times with large bending radius to fit into a static clearly defined housing. This technology the PCB manufacturing cost is higher than traditional FR-4 PCBs, but compared with rigid-flex PCBs, the cost is much lower.

Semi-flex PCB has been widely used in a lot of applications, including automotive industry.

If you have any semi-flex PCBs need to be produced, welcome to enquire.